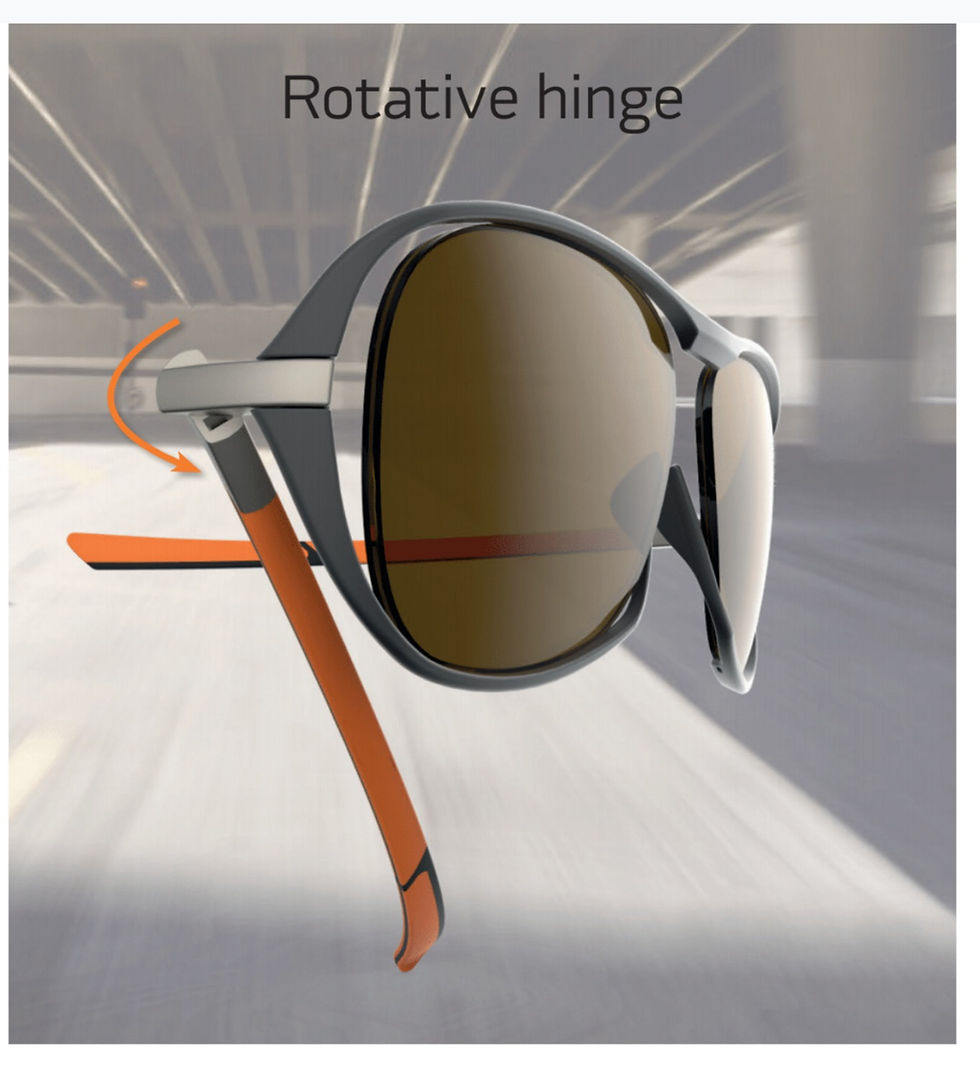

Titanium Rotative Hinge with PVD Coating

- Arthur Riley

- Jan 23, 2021

- 1 min read

Titanium MIM end pieces

The end pieces on our unique rotating hinges are made of MIM titanium. MIM stands for Molded Injection Metal.

The MIM Technology results in the injection of metal titanium mixture powder into a mold to create complex shapes. This unique manufacturing process gives to our end pieces an unparalleled metal strength structure and excellent finishing.

PVD coating

100% of our metal frames are finished with a PVD coating. PVD is the acronym for Physical Vapour Deposition, which literally means «vapour phase physical coating». It is a process done under vacuum at temperatures generally between 150 and 500 ° C.

The frames are placed in the vacuum chamber, heated first then ion etched by bombardment with argon ions, to create a pure and clean metal surface, free from any atomic contamination ready for the fusion in the matrix of the colour. This cutting-edge procedure guarantees deeply encrusted colour. Thanks to this very high-end finishing process, colours won’t chip, won’t fade. The colours are UV and wear resistant.

Comments