3D Printed Titanium Production

- Joanna Taylor

- Jan 24, 2021

- 1 min read

The Direct Metal Laser Sintering (DMLS) is an additive manufacturing technique of melting fine metal particles with a laser. An arm spreads a thin layer of extremely fine titanium

powder down into the printing bed while a powerful carbon dioxide laser is used to melt the powder and fuse the titanium together.

The process is repeated layer by layer until the frame is “printed» (created). 3D Printed Titanium Front The first of its kind on the world.

The 3D Printed Titanium process used with McLaren Vision frames is a cutting-edge technology with many advantages over traditional manufacturing processes:

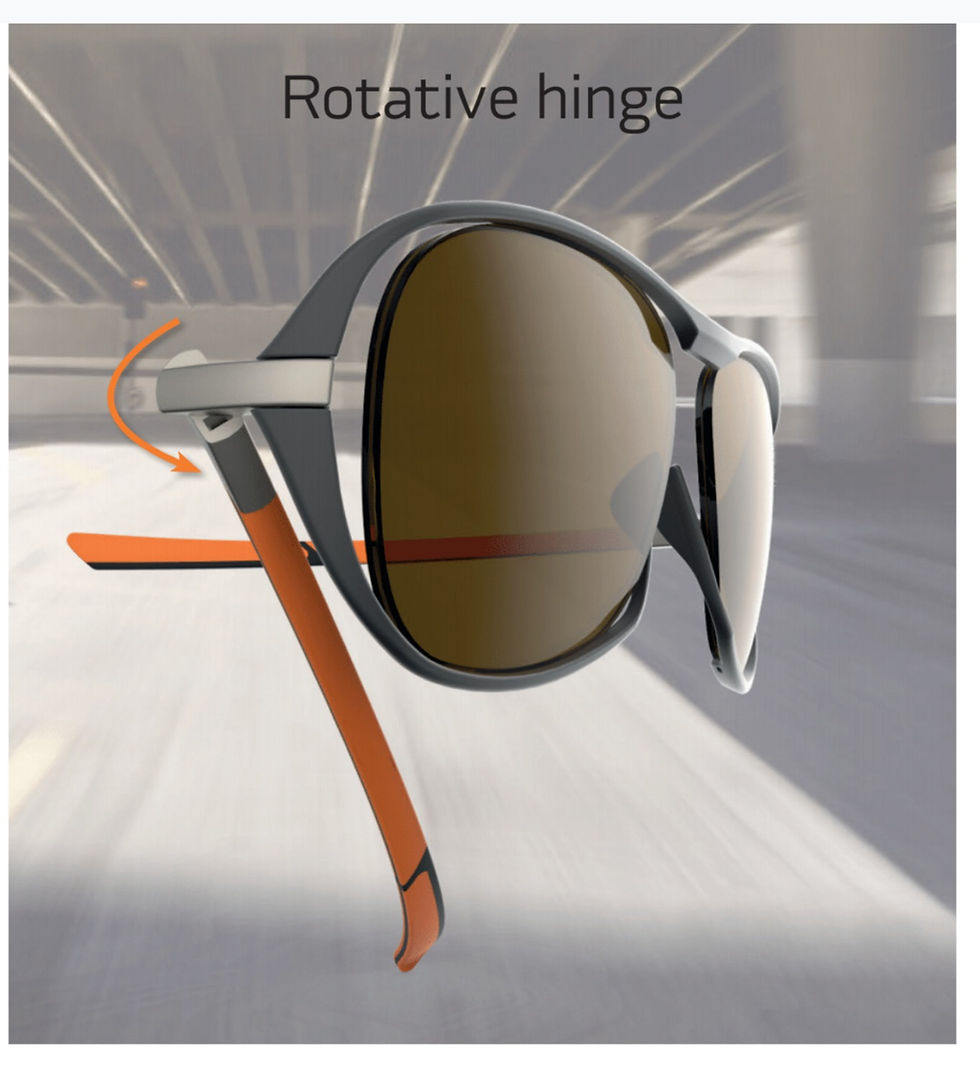

- Complex Design: 3D Printed Titanium makes possible the creation of complex shapes that are not possible by other conventional manufacturing methods. This process opens wide possibilities in terms of design and optimization.

- Mechanical properties: titanium printed parts have excellent mechanical properties and robustness because they are made in one solid block: no parts welded

together, thus reducing areas of weakness. This technology does not allow to manufacture identical series, each frame produced is unique.

Comments